Coldblock – Yeast management and fermentation challenges and solutions for breweries

Professional equipment for the fermentation process

A consistent, reliable and effective fermentation process relies on equipment that guarantees high-quality yeast management, hygienic design and accurate control of the process variables.

Our cold block process solutions help overcome common issues to unlock the full potential of your brewery process line.

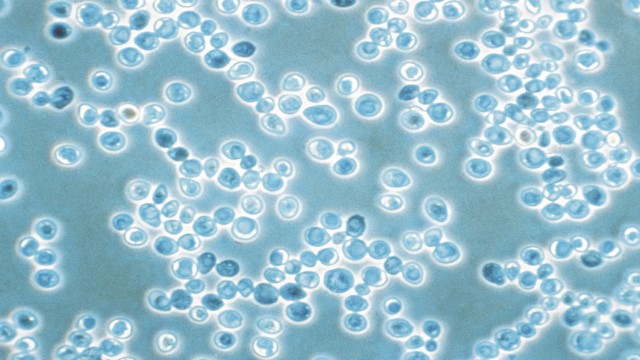

Yeast management and fermentation

Yeast management and fermentation are essential parts of the cold block. Equipment to prevent contamination and ensure high yeast viability is essential for a consistent, reliable and effective fermentation process.

Challenge

- High cost

- Reliance on commercial yeast strains

- Limited opportunity for creativity

Solution

- Yeast Management Systems:

- Alfa Laval 3-in-1 yeast module, or

- Alfa Laval Yeast propagation plant

Outcome

- Ability to rehydrate, propagate and re-use yeast

- Fully customizable solution

Challenge

- Inconsistent or slow fermentation profile

Solution

Outcome

- Up to 40% faster fermentation

- Improved homogenization during fermentation

- Optimized alcohol extract yield

- Flexibility – mobile unit that can be moved between tanks

Challenge

- Long sedimentation time

- High beer loss

- High turbidity

- Low yield

- Need to grow production capacity

Outcome

- Increased production capacity owing to speed of clarification without the need to expand fermenting capacity

- Beer recovery up to 15% compared with draining

- Ability to clarify beer when profile is right

- Extended shelf-life unblemished by haze (especially important for exports)

- Fast emptying of separators also means higher rotation of tanks which provides extra capacity without further investment

- Average 3% increase in yield between fermenting vessel and bright beer tank depending on operating procedures

- Up to 8% yield improvement in low to medium flocculating yeast strains

Challenge

- Need for yeast propagation, storage and recovery

Solution

Outcome

- Healthy yeast alternative with high viability and vitality

- Correct pitching

- High flexibility for propagating, storing and pitching different yeast strains

Challenge

- Ensuring the supply of uninfected, freshly propagated, high-quality yeast

Solution

- Alfa Laval SCANDI BREW line of yeast agitators

Outcome

- Yeast with high viability and vitality

- Correct pitching

- Homogenous yeast slurry

- More flexibility for propagating, storing and pitching different yeast strains

Challenge

- Foaming issues when wanting to improve fermenter utilization

- Repeatability of fermentation process

Solution

- Alfa Laval Rotary jet mixers installed in fermenters

Outcome

- Less foaming allows increased use of overall fermenter capacity

- Homogeneous distribution to prevent premature settling of yeast

- Uniform temperature and CO2 levels

- Consistent and shorter fermentation time

Challenge

- Long overall process time in fermenters

Solution

Outcome

- Energy efficient crash cooling

- Desired temperature reached while transferring green beer

Challenge

- Subpar hygiene in fermentation systems and interconnecting transfer lines

Outcome

- Product contact areas effectively and reliably cleaned

- Optimization of uptimes

Challenge

- Excess yeast

Solution

Outcome

- Recover up to 88% of your beer from yeast bottom

Dry hopping

Dry hopping is the process of adding hops following fermentation to add more aroma to the beer. Traditionally, dry hopping is done in beer styles such as pale ales and IPAs but is being utilized in the brewing of other beer styles as well.

Challenge

- Slow process and beer loss

Solution

- Alfa Laval dry hopping equipment:

Outcome

- Maximized use of hops

- Accelerated dry hopping process

- Homogenization of beer streams to improve downstream hop removal via centrifugation

Challenge

- Low yield

- Repeatability

- Extended process time when dry hopping on a large scale

Outcome

- Maximized use of hop

- Accelerated dry hopping process

- Improved downstream clarification

- Improved hop removal

Beer sampling

In the beer quality assurance process, two methods are employed for sampling: sterile and non-sterile. Sterile sampling involves pressing the “sterile” button to steam sterilize the pipeline before pressing “sampling” to collect the sample, followed by a flush with water and steam. Non-sterile sampling skips the sterilization step but follows a similar process, initiating with the “sampling” button and then proceeding with CIP cleaning of valves and pipelines along with the tank.

Challenge

- Inconsistent, unhygienic and time-consuming product sampling

Outcome

- Increased sampling quality and frequency

- Reduced time spent taking samples

Overall design

Breweries have different needs that must be considered while maintaining high sanitary standards and delivering high production efficiency. Our process expertise, along with our professional systems and technologies, enable you to fine-tune delicate production balances, use less energy and water, reduce waste and produce remarkable beers.

Challenge

- Safe operation of large vessels (yeast management, fermentation, bright beer tanks)

Solution

Outcome

- Integrated safety systems

- Consistent, repeatable and hygienic operation

Challenge

- Suboptimal cold block design

Outcome

- Avoidance of contamination

- Optimization of pumps and lines

- Optimization of complete process and utilities

- Increased level of process flexibility

Not sure which solution is right for you?

Alfa Laval's brewing process expertise, solutions and individual components for each process block can help you avoid and overcome common issues in the brewing process. Contact us to speak to an Alfa Laval brewing expert today.