2022-09-12 Product news

Optimized Alfa Laval Smit LNG design delivers proven performance with new flexibility and speed

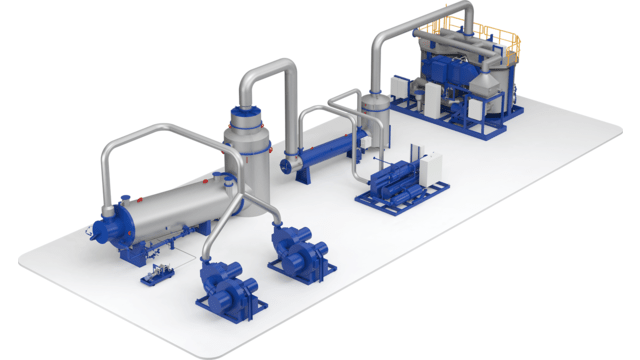

Alfa Laval has optimized the design of the Alfa Laval Smit LNG inert gas generator, bringing greater flexibility to an industry-leading solution. Modular construction with a range of options will mean more choice and faster access to vital safety equipment.

Modularity lets customers decide

The Smit LNG system is known for its very dry, high-quality inert gas, which is produced with Alfa Laval’s unique UltramizingÒ principle. The fuel is atomized by steam, ensuring not only less soot in the cargo tank after inspection, but also lower NOx emissions. This high performance is now even more readily available, thanks to a modularized Smit LNG design.

“The Smit LNG system is the same in terms of quality and reliability,” says Erik Haveman, Head of Inert Gas Systems at Alfa Laval. “What’s different is the flexible configuration, which comes from splitting the system into a number of standardized modules. All class and safety requirements are fulfilled by the most basic arrangement, to which customers can add the options they wish.”

Faster from request to finished design

The shift to modularity streamlines costs for customers, as they only pay for the Smit LNG options they select. Above all, it strengthens Alfa Laval’s cooperation with shipyards, since finished drawings can be supplied quickly – with no variation from system to system.

“There are no surprises with today’s Smit LNG system, either in performance or design,“ says Haveman. “For shipyards, the lead times are shorter and the predictability is 100%. Having examined RFQs from all major LNG yards when creating it, we can meet any yard request with the new modular approach.”

A platform with lasting advantages

For shipowners, modularity means long-term benefits as well. Servicing Smit LNG systems will be quicker and simpler, thanks to a reduced number of standardized parts. Spare parts stock will be easier to manage, and troubleshooting will be faster in the unlikely event of an issue.

“Less variation means less to investigate, so standardizing the Smit LNG system adds to the already high peace of mind,” Haveman concludes. “In addition, it gives us a stronger platform for further development. Customers have long entrusted us with their vessels’ safety, and they can expect us to continue moving it forward.”

To learn more about the Alfa Laval Smit inert gas system and Alfa Laval’s approach to inert gas production, please visit: www.alfalaval.com/marine

For further information, please contact:

Erik Haveman

Head of Inert Gas Systems

Alfa Laval Marine Division

Phone: +31 24 352 3225

E-mail: erik.haveman@alfalaval.com

Geertje van Duijne

Marketing Communications Manager, Business Unit Gas Systems

Alfa Laval Marine Division

Phone: +31 24 352 3239

E-mail: geertje.vanduijne@alfalaval.com

Editor’s notes

This is Alfa Laval

Alfa Laval is a world leader in heat transfer, centrifugal separation and fluid handling, and is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day.

Alfa Laval has 17,900 employees. Annual sales in 2021 were SEK 40.9 billion (approx. EUR 4 billion). The company is listed on Nasdaq Stockholm.