Investigating sustainable strategies across Canadian manufacturing factories

In the current global economy, Canadian manufacturing companies face intense pressure to maintain their competitiveness and maximize profits. Let's explore some of the challenges Canadian manufacturing plants face and outline steps they can take to build a greener future in manufacturing.

DATE 2024-07-20

In the current global economy, Canadian manufacturing companies face intense pressure to maintain their competitiveness and maximize profits. Accounting for about 10% of Canada's total GDP, amounting to approximately $174 billion, manufacturers export over $354 billion annually, making up 68% of Canada's merchandise exports.

However, there is also mounting pressure from regulators, shareholders and consumers to adopt sustainable development practices to lessen the environmental impact, reduce resource usage, and increase long-term profitability.

It's not an easy task, but these goals are much easier to achieve with the right expertise and equipment from Alfa Laval. In this blog, we’ll explore some of the challenges Canadian manufacturing plants face and outline steps they can take to build a greener future in manufacturing.

Mapping the green transition

How are Canadian industries investing and working towards sustainability goals? Find out in our eBook "Mapping the green transition: Benchmarking progress in Canada’s manufacturing and industrial sectors."

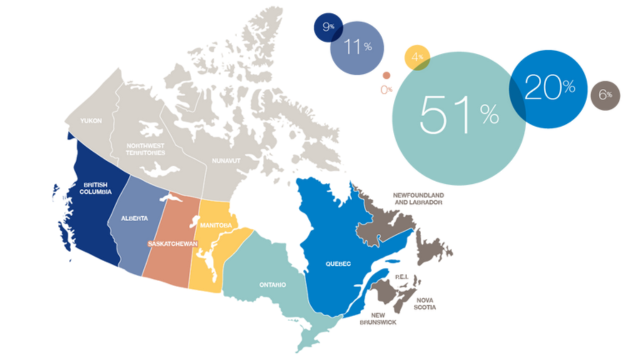

Who Did We Survey?

For the purpose of this survey, we interviewed employees of general manufacturing plants across Canada. 51% of respondents were located in Ontario, followed by Quebec at 20%. Alberta was next at 11%, followed by British Columbia at 9%. Only 6% were from the Atlantic region, and 4% were from Manitoba.

In terms of job title, 22% identified as C-suite, 16% were Plant Operations Managers, while 15% of respondents were Plant Engineering Managers and Plant Managers. Process Engineers made up 11% of our respondents and Plant Maintenance Managers made up 7%, with Plant General Managers and Maintenance Managers accounting for 6% of survey respondents. Only 4% reported working as a Sustainability Director or Manager.

Sustainability Practices: A Breakdown

Most Canadian manufacturing plants are serious about sustainability, with 82% reporting they have sustainability goals in place. Only 13% said they had not yet set any goals, and 6% weren’t sure. Of those that have a plan in place, 78% said they were investing in new equipment, 73% are optimizing their processes, and 71% are focusing on employee training.

When we asked for more details on how these plants were optimizing their processes, 42% said they focused on effective channelizing and/or organizing processes, with 18% turning to reducing defects and/or rework. Meanwhile, 33% said they prioritize overall efficiency, with 15% specified working towards being more energy efficient.

Strategies to Increase Sustainability

We then asked manufacturing plants which sustainability strategies they were exploring. The majority (78%) said they were improving their energy efficiency, followed by waste reduction and recycling programs (67%), water conservation initiatives (49%) and the use of renewable energy sources (44%).

How else are respondents optimizing their processes?

Energy reducing programs

- 67% are reducing electrical energy consumption

- 53% are reclaiming waste thermal energy

- 51% are switching to renewable or less carbon-intensive energy sources

- 51% are reducing energy thermal consumption

Waste energy recovery

- 67% are recovering waste energy

- 29% are not recovering waste energy

- 4% aren’t sure how they’re recovering waste energy

Waste energy reuse

- 71% are reusing waste energy

- 27% are not reusing waste energy

- 2% aren’t sure how they’re reusing waste energy

Wastewater reclamation

- 64% are focusing on water reduction strategies

- 58% are focusing on water recovery strategies

- 51% are focused on water reclamation for other parts of their business processes

- 4% said wastewater reclamation isn’t part of their sustainability goals

Turn waste into value

The Alfa Laval AlfaFlash ZLD system can help your manufacturing plant meet changing regulations and lower your disposal costs by reducing wastewater.

Challenges and Barriers to Sustainability Goals

62% of our respondents said financial constraints hindered their sustainability progress, while 51% said a lack of understanding of sustainable practices was their biggest hurdle to overcome. Technological limitations were cited by 44% as their top obstacle, and concerns about regulatory compliance by 44% as their biggest barrier to sustainability.

All over the world, Alfa Laval is helping manufacturing plants accelerate towards more efficient, cleaner energy solutions and maximize sustainability through our expertise in:

- Clean Energy

Alfa Laval can help customers transition to cleaner energy with a wide range of advanced heat transfer and separation technologies including clean hydrogen, fuel cells, Power-to-X, biofuels, carbon capture, concentrated solar power and more. - Circular Economy

Thanks to our unique understanding of separation and thermal technologies, Alfa Laval has led the way in the development of new solutions to advance the circular economy, helping optimize production processes for reliability and sustainability. - Energy Efficiency

At Alfa Laval, we have spent decades developing plate heat exchanger technologies that help manufacturing plants recover high-temperature heat generated by industrial processes and reuse it for other applications. - Fluid Power

From the plastic industry, power pack manufacturers, hydraulic presses, the paper industry, machine tool manufacturers and more, Alfa Laval helps customers cool down or filtrate hydraulic oils and lube oils for maximum performance. - Metalworking

Alfa Laval supplies a broad range of heating, cooling and fluid cleaning solutions for the metalworking industry to ensure accurate temperature control and efficient cleaning, whatever the process.

Run Your Plant Sustainably with Alfa Laval

Teaming up with Alfa Laval means you’ll have access to innovative solutions that enable your manufacturing plant to minimize waste, maximize resource utilization, reduce emissions and foster a culture of sustainability.

Our deep industry knowledge means we know how to optimize your customer processes and overcome the challenges you face in transitioning to a greener, cleaner production line.

It’s a win-win partnership for you and the planet.

Learn how Alfa Laval’s range of cutting-edge fluid cleaning solutions can cut your plant’s operating costs and increase your profit margin. Contact one of our experts.